- BOLT

- BT-CB1600S/CB1600

Servo CNC Busbar Bending Machine: 350KN servo-driven force, PLC control, and HIWIN precision for copper/aluminum busbars. Ideal for switchgear, transformers, and busway industries. No oil, low noise, high efficiency!

Product details

INTRODUCTION

The Servo CNC Busbar Bending Machine is designed for bending copper and aluminum busbars. This machine utilizes a high-power servo motor as the driving force, combined with a PLC control unit. It offers high processing efficiency, precise positioning, and an automation level that leads the industry. It is widely used in high/low-voltage switchgear, transformer manufacturing, box substations, busways, and other related industries.

Technical parameters

CNC Servo CNC Busbar Bending Machine | BT-CB1600S | BT-CB1600 | |

|---|---|---|---|

| Nominal force | 350KN | 500KN | |

| Drive mode | Servo | Hydraulic | |

| Max. bending stroke | 220mm | 220mm | |

| Length of block gauge | 1600mm | 1600mm | |

| Precision of block gauge | ±/- 0.1 (100mm) | ±/- 0.1 (100mm) | |

| Bending precision | ±/- 0.5 | ±/- 0.5 | |

| Repeat location precision | ±/- 0.1 | ±/- 0.5 | |

| Max. processing thickness | 12mm | 15mm | |

| Max. processing width | 200mm | 200mm | |

| Max. speed of block gauge (X-axis) | 15m/min | 15m/min | |

| Speed of bending (Y-axis) | Fast 5 m/min, Slow 1.25m/min | Fast 5 m/min, Slow 1.25m/min | |

| Power motor of block gauge | 0.75kW | 0.75kW | |

| Main motor power | 5.0kW | 5.0kW | |

| Out dimension | 4200×1800mm | 4200×1800mm | |

| Total weight | 2600KG | 2800KG | |

| Main electrical accessories suppliers (Custom service can be customized according to customer requirements) | |||

| Serial number | Components and parts | brand | Number |

| 1 | X, Y axis servo motor | Siemens | 2 sets |

| 2 | AC contactor | Schneider | 1 set |

| 3 | thermal relay | Schneider | 1 set |

| 4 | PLC | Siemens | 1 set |

| 5 | Sensor | OMRON | 1 set |

| 6 | Touch screen | Taiwan Panel Master | 1 set |

MAIN FEATURES

(1) Mechanical Structure

Servo CNC Busbar Bending Machine adopts an open bending structure with a fully welded working platform. Through vibration aging and heat treatment, internal stress is eliminated, ensuring high stiffness and strength. The main drive section and work platform are organically integrated, providing excellent material accessibility and a clear observation view.

(2) Main Drive Section

The main drive employs a servo-driven system, featuring a compact design, powerful performance, and user-friendly operation. It eliminates oil contamination, reduces noise, and occupies minimal space, making it environmentally friendly and practical. With an output force of 350KN, the servo drive ensures precise synchronization with the PLC, enabling fast forward, fast retreat, and slow inching functions. This enhances processing efficiency and bending accuracy, surpassing traditional hydraulic drive machines. Equipped with a high-power, high-inertia servo motor, it supports optional bending dies for horizontal bending, vertical bending, and twisting operations.

(3) X-Axis Block Gauge

The block gauge adopts a modular design, allowing customized lengths based on customer requirements. It is driven by a servo motor, high-precision Taiwan-made HIWIN ball screw, and linear guide rail, ensuring smooth operation and high positioning accuracy. The X-axis maximum stroke is 1600mm (customizable upon request).

(4) Electrical Components

The system features a Taiwan-made Panel Master touchscreen and proprietary bending software developed by our company. The interface is intuitive and user-friendly, enabling easy operation even for non-professional workers.

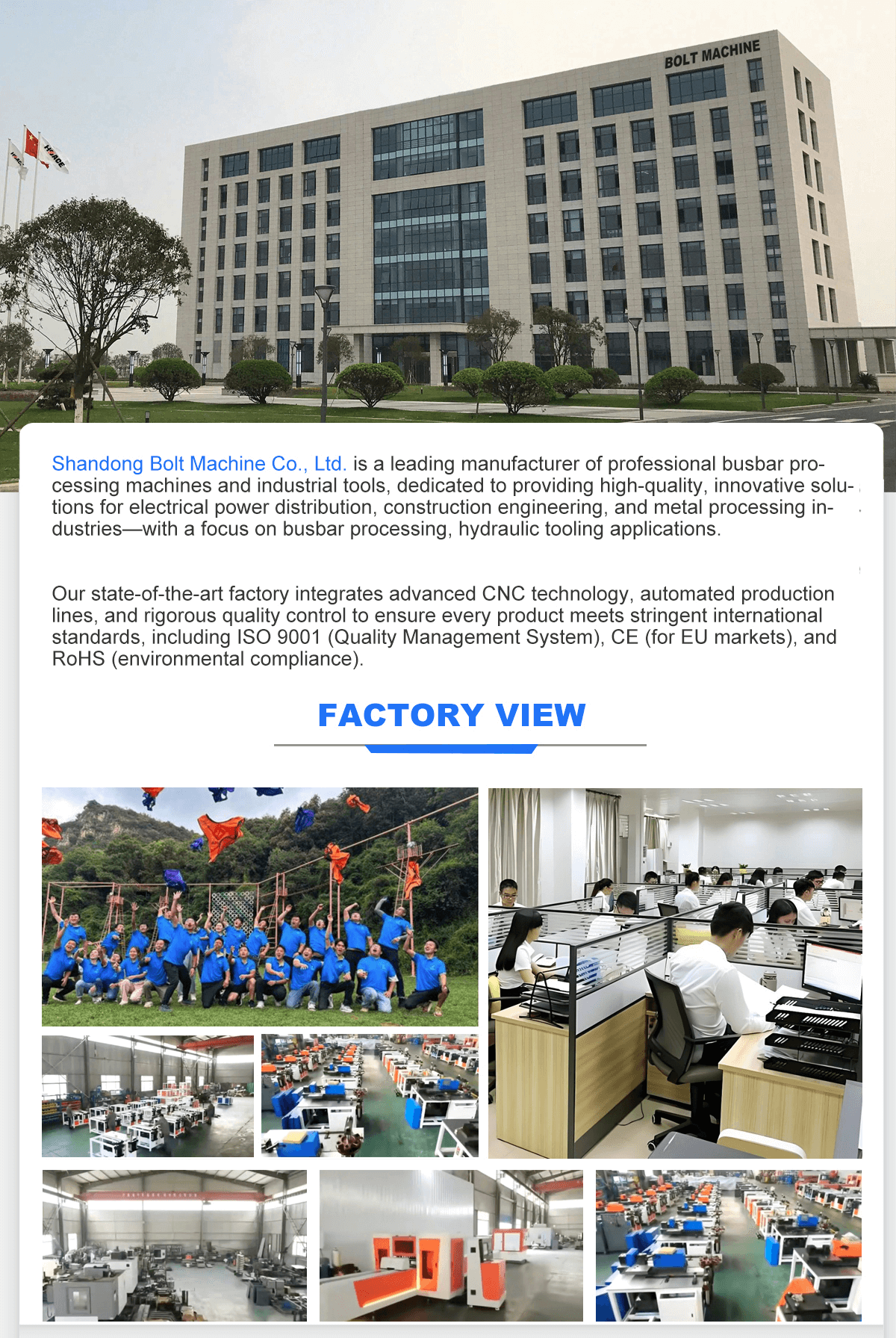

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures