- BOLT

- BT-C303C/BT-C503C/BT-C803C

The Closed-Type CNC Double Table Busbar Processing Machine integrates punching, shearing, and bending with Siemens PLC control for precision (±1° bending accuracy). Featuring dual worktables, 3 stations operate simultaneously to boost efficiency—handles copper/aluminum busbars up to 250mm width. Equipped with a 6-in-1 turret punching structure, dual safety controls, and surface protection, it supports custom dies for special processing (flattening, twisting, crimping). CE & ISO 9001 certified, ideal for batch production.

Product details

Closed-Type CNC Double Table Busbar Processing Machine features punching, shearing, and bending workstations. These stations can operate simultaneously or sequentially, significantly reducing processing time and boosting production efficiency. The bending station utilizes Siemens PLC control (Germany). Its primary function is processing copper and aluminum busbars of various specifications. Simply select the required workstation to quickly and conveniently perform operations on copper/aluminum bars, including shearing, punching (round holes, elongated holes), horizontal/vertical bending, U-bending, embossing, flattening, twisting, and cable lug crimping.

Punching Unit:

Six-in-One Turret Structure: Precision-engineered from ductile iron forging, ensuring absolute concentricity of upper and lower dies.

Versatile Tooling: Holds 6 punch dies for 6 hole types. Accommodates dies of different sizes/shapes, eliminating frequent changeovers. CNC-machined die mounting holes ensure high precision and long service life.

Triple Positioning: Positioning pins, ruler, and optical guide.

Surface Protection: Ensures no surface marks on workpieces.

Custom Hole Capability: Utilizes specialized dies for non-standard holes (e.g., round, square, elliptical).

Dual Safety Controls: Foot pedal and push-button limit switches.

Shearing/Cutting Unit:

Precision Cut: Sharp blades with dual-column shear structure guarantee flat, clean cuts – no droop, burrs, or scrap.

Dual-Pressure System: Prevents material lifting at corners.

Dual Safety Controls: Foot pedal and push-button limit switches.

Bending Unit:

Dual Worktables: Enables simultaneous, non-interfering operation of all three units (shear, punch, bend).

Closed Bending Structure: Ensures uniformity during flat bending and embossing, enhancing repeat positioning accuracy for batch production.

Siemens PLC Control: Delivers high bending precision (±1° bend angle accuracy, ±0.5° repeatability).

Multi-Function via Tooling: Change dies for horizontal bends, vertical bends, U-bends, embossing, flattening, twisting, and lug crimping. Features automatic bend angle control.

Efficiency & Storage: System includes memory function for easy storage and recall of settings. Automatic stop timers per station enhance energy efficiency.

Direct Input: Simply input height/length to produce parts (e.g., Z-bends).

Machine parameters

Closed-Type CNC Double Table Busbar

Processing MachineBT-C303C BT-C503C BT-C803C Nominal force (kn) 300 500 800 Punching dia. range (mm) φ4.3 - φ25 φ4.3 - φ30 φ4.3 - φ34 Max. thickness (mm) 12 16 20 Max. width (mm) 160 200 250 Max. shearing thickness (mm) 12 16 20 Max. shearing width (mm) 160 200 250 Max. horizontal bending width (mm) 160 200 250 Max. Horizontal bending thickness (mm) 12 16 20 Max. vertical bending size (mm) 10 × 100 10 × 120 10 × 120 Power (kw) 3 × 4KW 3 × 5.5KW 3 × 5.5KW Bending precision (degree) ±1° ±1° ±1° Repeat bending precision (degree) ±0.5° ±0.5° ±0.5° First table size (mm) 1750 × 1250 1920 × 1385 1920 × 1385 Second table size (mm) 985 × 500 985 × 500 985 × 500 Outside dimension (mm) 1780 × 1400 × 1300 1950 × 1560 × 1390 1950 × 1560 × 1450 Container size (mm) 1870 × 1480 × 1520 2060 × 1660 × 1650 2060 × 1660 × 1650 Total weight (kg) 1450 1800 2100

| Mold List (Optional) | ||||

|---|---|---|---|---|

| No. | Name | Unit | Qty | Remarks |

| Punching Molds | ||||

| 1 | Punching Mold φ7 | Set | 1 | Punching molds can be made for diameters ranging from φ4.3 to φ25. Standard models allow selection of 8 sets, and custom molds can be made according to customer requirements. |

| 2 | Punching Mold φ9 | Set | 1 | |

| 3 | Punching Mold φ11 | Set | 1 | |

| 4 | Punching Mold φ13 | Set | 1 | |

| 5 | Punching Mold φ15 | Set | 1 | |

| 6 | Punching Mold φ17 | Set | 1 | |

| 7 | Punching Mold φ19 | Set | 1 | |

| 8 | Punching Mold φ21 | Set | 1 | |

| 9 | Punching Mold φ9×13 | Set | 1 | |

| 10 | Punching Mold φ11×15 | Set | 1 | |

| 11 | Punching Mold φ13×18 | Set | 1 | |

| 12 | Punching Mold φ17×21 | Set | 1 | |

| Chamfering molds R10, R15 available as optional extras | ||||

| Flat Bending Molds | ||||

| 1 | Flat Bend R3 | Set | 1 | Three sets of flat bending molds |

| 2 | Flat Bend R5 | Set | 1 | |

| 3 | Flat Bend R10 | Set | 1 | |

| Vertical Bending Molds | ||||

| No. | Name | Unit | Qty | Remarks |

|---|---|---|---|---|

| 1 | Vertical Bend R30 (for busbars ≤40mm width) | Set | 1 | Select 1 set |

| 2 | Vertical Bend R50 (for busbars ≤60mm width) | Set | 1 | |

| 3 | Vertical Bend R80 (for busbars ≤100mm width) | Set | 1 | |

| Other Molds | ||||

| - | Embossing Mold | Set | 1 | Standard |

| - | U-Bend Mold | Set | 1 | Standard |

| - | Small Twist Mold (20mm-50mm) | Set | 1 | Optional (besides standard) |

| - | Large Twist Mold (50mm-120mm) | Set | 1 | Optional (besides standard) |

| - | One-time Forming Mold | Set | 1 | Optional (besides standard) |

| Main Equipment Configuration | |

|---|---|

| Motor: | Nanjing Shunbai |

| Gear Pump: | Taiwan Xin Hong |

| Solenoid Valve: | Shanghai Yanran |

| Contactor: | Schneider |

| CNC System PLC: | Panasonic (Siemens optional) |

| Display: | P-Touch |

| Relay: | Schneider |

| Buttons: | CHINT |

| Punching Molds: | Standard 8 sets (customer selectable): φ7, φ9, φ11, φ13, φ17, φ21, φ13×18, φ17×21 |

| Flat Bending Molds: | Three sets (R3, R5, R10) |

| Vertical Bending Molds: | R50 one set, Embossing one set, U-Bend one set |

| Punching Unit Turret: | 6 stations |

| Turret Material: | Ductile cast iron, integral molding |

| Punching/Shearing Column: | φ60 polished rod |

| Hydraulic Oil Tank: | Self-made, 3mm steel plate, phosphating treatment |

| Shearing Blade: | One set (on the machine) |

| Hex Key Tool Set: | One set |

| Hydraulic Seals: | One set |

| Equipment User Manual: | One copy |

| Oil Funnel: | One set |

| Foot Switches: | Three sets |

Certifications:

CE Marking (EU Standards)

ISO 9001 Certified

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

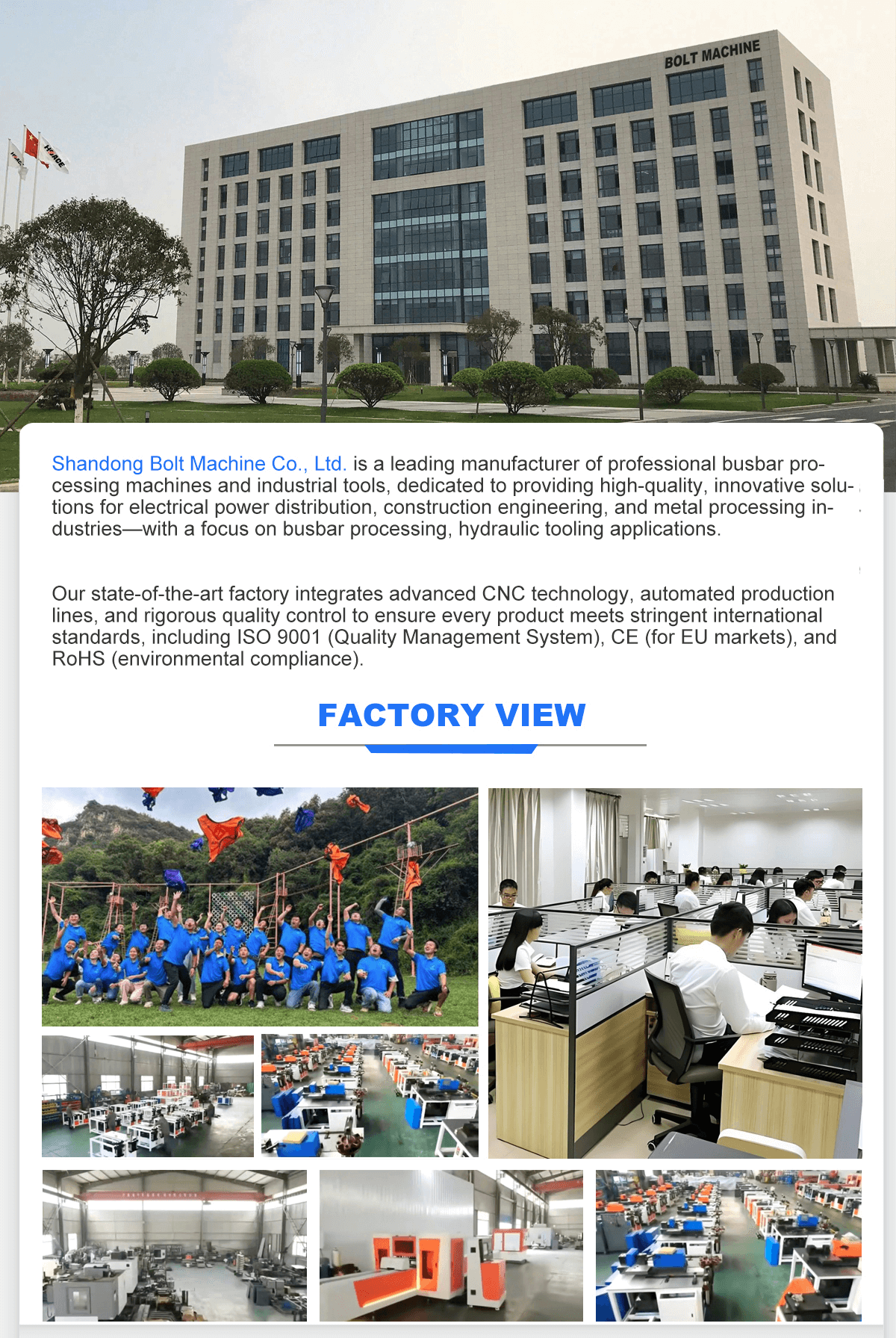

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures