- BOLT

- BT-M303C/BT-M503C

This series busbar processing machine integrates shearing, punching, bending and other functions, which can efficiently process copper and aluminum busbars. The shearing is burr-free with flat cuts; the punching has high precision and long die life; the bending positioning is accurate, suitable for mass production. It supports dual control of manual buttons and foot pedal, with simple operation. It can also be customized with dies to meet special processing needs (such as flattening, twisting, etc.), making it an ideal choice to improve the efficiency and quality of busbar processing.

Product details

Closed-Type Manual Control Busbar Machine features independent Punching, Shearing, and Bending units. The working stroke of each unit is easily adjustable, shortening processing time, boosting productivity, and simplifying operation. Operators can master the machine within minutes, enabling higher efficiency and faster operation.

Primary Functions: Process copper and aluminum busbars of various specifications. Using the corresponding unit, easily and swiftly perform:

Shearing: Cut copper/aluminum bars

Punching: Create round holes, elongated holes (via replaceable dies)

Bending: Perform flat bends, vertical bends, and embossing

Special Processing (via die replacement): Flattening, twisting, cable lug crimping, U-bending.

Product Parameters

| Closed-Type Manual control Busbar Machine | BT-M303C | BT-M503C |

|---|---|---|

| Max. Punching Force (Kn) | 300 | 500 |

| Punching Processing Range (mm) | Φ4.3-Φ25 | Φ4.3-Φ32 |

| Max. Processing Thickness (mm) | 12 | 16 |

| Max. Processing Width (mm) | 150 | 200-250 |

| Max. Shearing Force (Kn) | 300 | 500 |

| Max. Shearing Depth (mm) | 12 | 16 |

| Max. Shearing Width (mm) | 150 | 200-250 |

| Max. Flat Bending Force (Kn) | 300 | 500 |

| Max. Flat Bending Width (mm) | 150 | 200-250 |

| Max. Flat Bending Depth (mm) | 12 | 16 |

| Max. Vertical Bending Width (mm) (at 10mm thickness) | 100 | 100 |

| Overall Dimensions (mm) | 1500×1350×1260 | 1800×1550×1400 |

| Main Motor Power (Kw) | 4 | 5.5 |

| Machine Weight (Kg) | 1200 | 1700 |

| Bending Accuracy | Manual Adjustment | |

Product Features:

Shearing Unit:

Employs universal guillotine shearing.

Delivers clean, flat cuts without collapse, burrs, or waste material.

Ensures aesthetically pleasing results.

Punching Unit:

Features a monolithic square structure for superior visibility and strength.

Guarantees absolute alignment between upper and lower dies, enhancing concentricity.

Extends die lifespan significantly.

Processes different holes by simply changing dies.

The punching station is equipped with a mechanical bidirectional positioning device

Bending Unit:

Utilizes an enclosed monocoque frame structure.

Ensures uniform pressure during flat bending, vertical bending, and embossing.

Greatly improves repeatable positioning accuracy for batch production.

Extends service life.

Horizontal processing design ensures safer and more convenient operation.

The workstations adopt a double-layer workbench, and the three workstations can operate simultaneously without interfering with each other.

Operation & Flexibility:

Offers dual control: manual buttons and foot pedal for simple, intuitive use.

Customizable with specific dies or tooling to meet unique customer shape requirements.

Certifications:

CE certified (EU standards) & ISO 9001.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

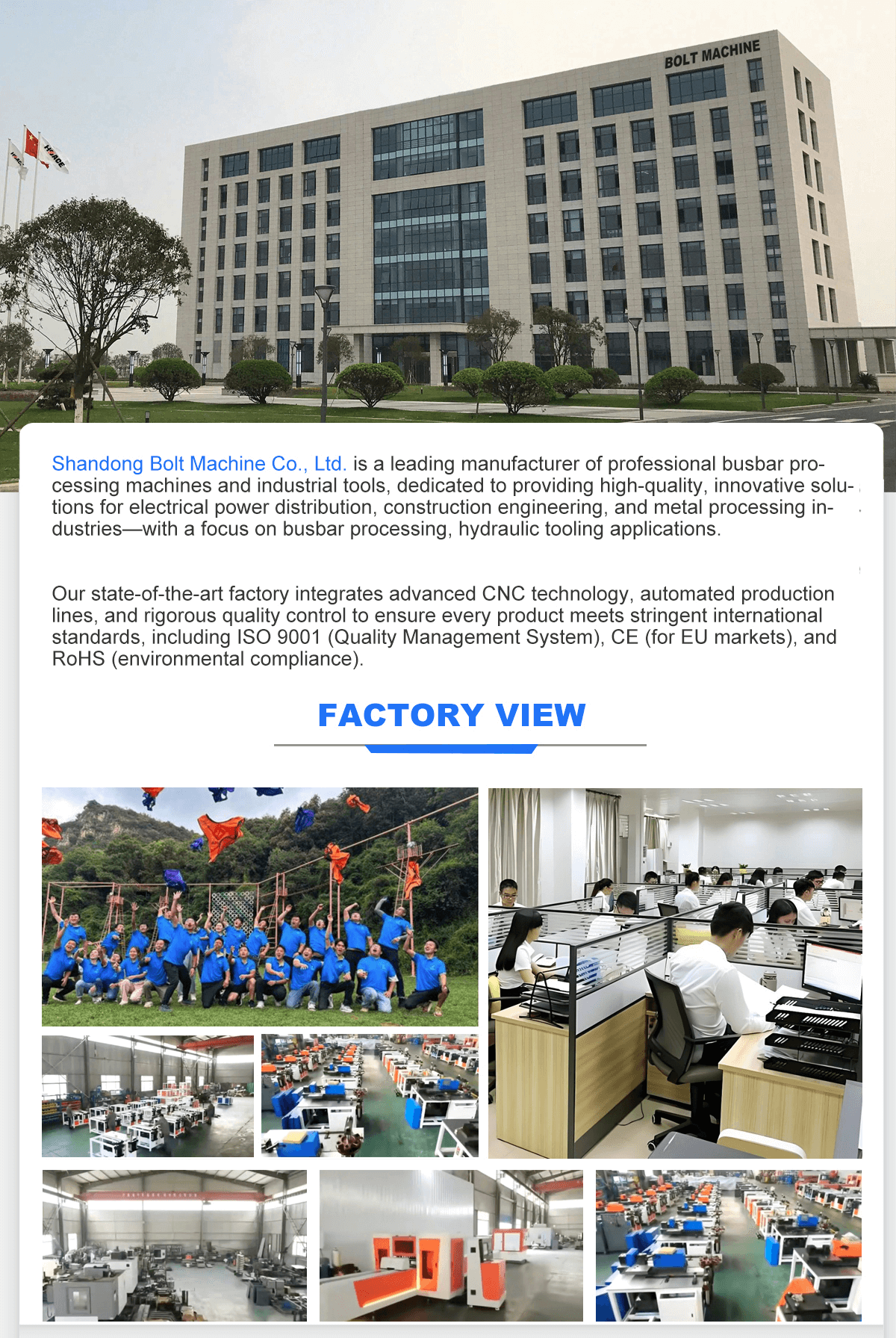

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures