- BOLT

- CH-60,CWC-150,CB-150D,HB-700A

Portable electric drive busbar processing machine: Cutting, punching, bending units for copper/aluminum busbars. Cutting Unit delivers clean, burr-free cuts; Punching Unit ensures accurate holes; Bending Unit offers ±1° precision. Powered by quality electric oil pump for stable hydraulic performance. Ergonomic design with dual operation modes. Models include CH-60 puncher, CWC-150 cutter, CB-150D bender. 150/200 combo kits available. Fast delivery, export packaging.

Product details

Portable electric drive busbar processing machine: compact, electric-powered, ideal for on-site busbar punching, cutting and bending with easy mobility.

Key Units & Features:

-Cutting Unit: Adopts precision blades to deliver clean, burr-free cuts with minimal deformation, ensuring neat edges even for thick busbars. Suitable for copper, aluminum, and other conductive materials.

- Punching Unit: Enables quick hole punching. The stable structure ensures accurate positioning, avoiding offset or damage to the busbar.

- Bending Unit: Supports both horizontal and vertical bending with a precision of ±1°, meeting strict requirements for busbar shaping in electrical installations.

Powered by a high-quality electric oil pump, the machine delivers consistent hydraulic pressure for smooth, efficient operation—whether cutting thick materials, punching precise holes, or bending with accuracy. Its ergonomic handle and dual operation modes further enhance usability, reducing operator fatigue during long hours of work.

Technical Parameters:

BUSBAR PUNCHER

Model No. | Punch press | Max. Punch thickness | Max. Punch depth | Weight | Punching die sizes(mm) |

CH-60 | 31 TON | 10MM | 95MM | 13.5KG | Ø10.5, Ø13.8, Ø17, Ø20.5 |

CH-70 | 35 TON | 12MM | 115MM | 28KG | Ø10.5, Ø13.8, Ø17, Ø20.5 |

BUSBAR CUTTER

Model No. | Rated Pressure | Max. Cut width | Max. Cut thickness | Machine size | Net Weight |

CWC-150 | 15 TON | 150MM | 10 MM | 410*275*180 MM | 26 KG |

CWC-200 | 20 TON | 200MM | 12 MM | 430*340*200 MM | 35 KG |

BUSBAR BENDER

Model No. | Rated Pressure | Max. Width. | Max. Thickness | Net Weight |

CB-150D | 16 TON | 150 MM | 10 MM | 17.5 KG |

CB-200A | 20 TON | 200 MM | 12 MM | 24 KG |

HYDRAULIC PUMP

Model No. | Rated pressure | Oil tank capacity | Motor power | Control way | Machine size | Net weight |

HB-700A | 63MPA | 5L | 750W | Foot switch | 350*270*490MM | 28KG |

Portable electric drive busbar processing machine :150/200 Model Busbar Processing Combination Kit

Pump options: Manual / Manual (with gauge) / Electric / Solenoid valve pump.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-5 days after payment.

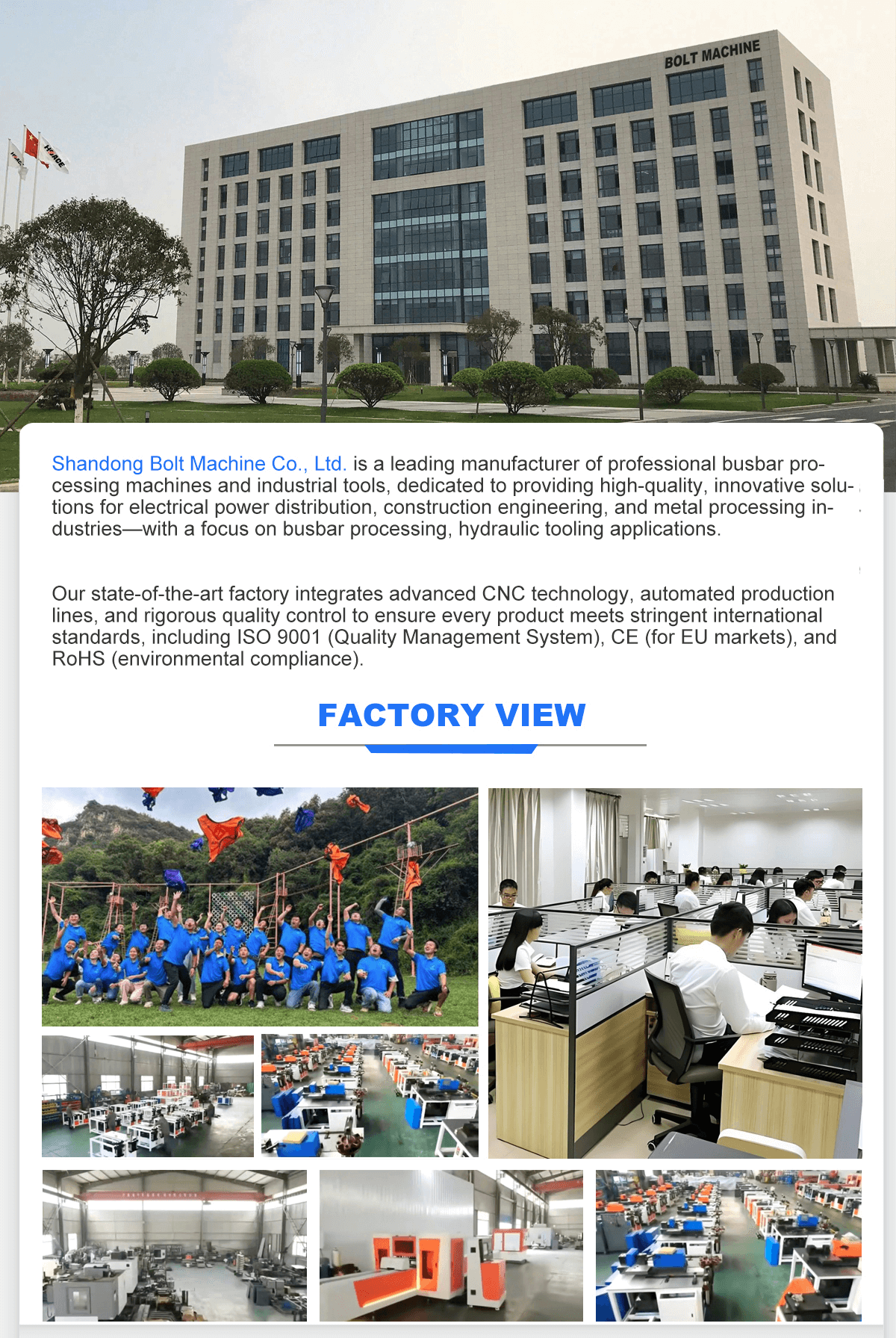

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures