- BOLT

- C303A,C303B,C303/503C,C303/C503D

The Open Type CNC Busbar Processing Machine integrates independent punching, shearing, and bending units, allowing simultaneous operation for efficient copper/aluminum busbar processing. Equipped with a six-station turret punch (Ø4.3-Ø36) and Siemens PLC control, it delivers ±1° bending precision. Ideal for switchgear and power transformer manufacturing, it supports custom dies, features dual operation modes (foot pedal + button), and comes with rich random accessories. Boost productivity with its high efficiency and low long-term costs.

Product details

Open-Type CNC Busbar Processing Machine integrates three independent processing units: Punching, Cutting/Shearing, and Bending. Designed to efficiently handle copper/aluminum busbars of various specifications, all units can operate simultaneously without interference. It features simple operation, high productivity, and is widely used in switchgear and power transformer manufacturing.

Punching Unit:

Six-Station Turret Structure: Ensures absolute concentricity of upper and lower dies, extending service life and reducing long-term costs. Punching dies are made of high-strength CR12MOV steel; the center crossbeam is reinforced to 120mm.

Multi-Size Capability: Six built-in punches create six standard hole sizes, eliminating frequent die changes and significantly reducing labor intensity.

Three Positioning Modes: Pin positioning, scale positioning, and optical positioning for convenient and precise alignment.

Special Dies Compatibility: Accommodates custom dies for non-standard holes (e.g., square, oval, countersunk).

Dual Operation Modes: Foot pedal switch and push-button control.

Cutting/Shearing Unit:

Shearing-Cut Technology: Produces clean cuts with no collapse, burrs, or waste material.

Powerful Hydraulic Cylinder: Equipped with a robust 300/500KN hydraulic cylinder.

Reinforced Structure: Thickened ductile iron center crossbeam ensures superior shear guidance and prevents cylinder loosening.

Dual Operation Modes: Foot pedal switch and push-button control.

Bending Unit:

Dual-Level Worktable: Enables efficient workflow.

Precision Control: Siemens PLC control system ensures high bending accuracy.

Versatile Forming: Interchangeable dies handle flat bends, vertical bends, U-bends, embossing, flattening, twisting, and pressure cable terminals. Directly input height/length for complex bends (e.g., Z-bends). Bending accuracy: ±1°, Repeat bending accuracy: ±0.2°.

Independent Work Surfaces: Allows simultaneous operation of all three units without interference.

Simple Operation: Manual push-button or foot pedal control.

Control Cabinet:

Advanced Control & Protection: Bending angles controlled by imported Siemens PLC NC system. Enhanced protection with 6 Schneider relays, safeguarding system contacts, extending machine life, minimizing downtime, and reducing maintenance costs.

Electrical Safety & Efficiency: Integrated transformer provides effective input/output circuit isolation for electrical safety and prevents interference. Maintains input/output power balance to improve circuit efficiency.

Hydraulic System:

Independent & Efficient: Features three motors and three pumps, enabling each unit to operate independently or concurrently without interference.

Smart Energy Saving: PLC automatically stops motors during idle periods for intelligent power savings and comprehensive energy efficiency.

Machine parameters

Function | C303D | C303C | C303B | C303A | |

Punching | Max. Punching Force (KN) | 300 | 300 | 300 | 300 |

Punching Diameter Range (MM) | Ø4.3-Ø36 | Ø4.3-Ø36 | Ø4.3-Ø36 | Ø4.3-Ø36 | |

Max. Thickness (MM) | 16 | 16 | 16 | 16 | |

Max. Width (MM) | 160 | 160 | 160 | 160 | |

Shearing/ Cutting | Max. Shearing Thickness (MM) | 16 | 16 | 16 | 16 |

Max. Shearing Width (MM) | 160 | 160 | 160 | 160 | |

Vertical Bending | Max. Bending Force (KN) | 500 | 500 | 500 | 500 |

Max. Thickness (MM) | 16 | 16 | 16 | 16 | |

Max. Width (MM) | 160 | 160 | 160 | 160 | |

Horizontal Bending | Max. Width (MM) | 100 | 100 | 100 | 100 |

Max. Angle (Degree) | 90° | 90° | 90° | 90° | |

Out Dimension | MM | 1720*1220*1240 | 1720*1220*1240 | 1720*1220*1240 | 1720*1220*1240 |

First table size | MM | 170x1250 | 1750x1250 | 170x1250 | 1750x1250 |

Second table size | MM | 985X500 | / | 985X500 | / |

Power | KW | 3*4kw | 3*4kw | 1*4kw | 1*4kw |

Weight | KG | 1500kg | 1480kg | 1400kg | 1380kg |

CNC Precision | Bending Precision | ±1° | ±1° | ±1° | ±1° |

Repeat Bending Precision | ±0.5° | ±0.5° | ±0.5° | ±0.5° |

Main component:

| No. | Accessory Name | Quantity | Brand |

|---|---|---|---|

| 2 | PLC | 1 | German Siemens (SIMATIC S7-200) |

| 3 | Touch Screen | 1 | Kunlun Tongtai |

| 4 | Draw-wire Encoder | 1 | Matera |

| 5 | Motor | 3 | Xiangtan Xiangdian |

| 6 | Contactor/Thermal Relay | 3 | Schneider |

| 7 | Relay | 6 | Schneider |

| Transformer | 1 | Lanpu | |

| 8 | Oil Pump | 3 | Taiwan Xin Hong HGP-3A-F11R |

| 9 | Relief Valve | 3 | Taiwan Youtian RF-G02-3-20 |

| 10 | Solenoid Valve | 3 | Taiwan Youtian DSG-03-3C6-20 |

Random Accessories

| No. | Accessory Name | Quantity | Unit |

|---|---|---|---|

| 1 | Punching Mold | 8 | set |

| 2 | Flat Bending Mold | 3 | set |

| 3 | Vertical Bending Mold | 2 | set |

| 4 | U-bend Mold | 1 | set |

| 5 | Oil Can | 1 | set |

| 6 | Hex Key | 1 | set |

| 7 | Hydraulic Seal Ring | 1 | set |

| 8 | Foot Switch | 3 | set |

| 9 | Limit Switch | 2 | pcs |

| 10 | Punching Locating Pin | 1 | pcs |

| 11 | Relay | 2 | pcs |

| 12 | Fuse | 1 | pcs |

| 13 | U-shaped Mold | 1 | set |

| 14 | Embossing Mold | 1 | set |

Certifications:

CE certified (EU standards) & ISO 9001.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

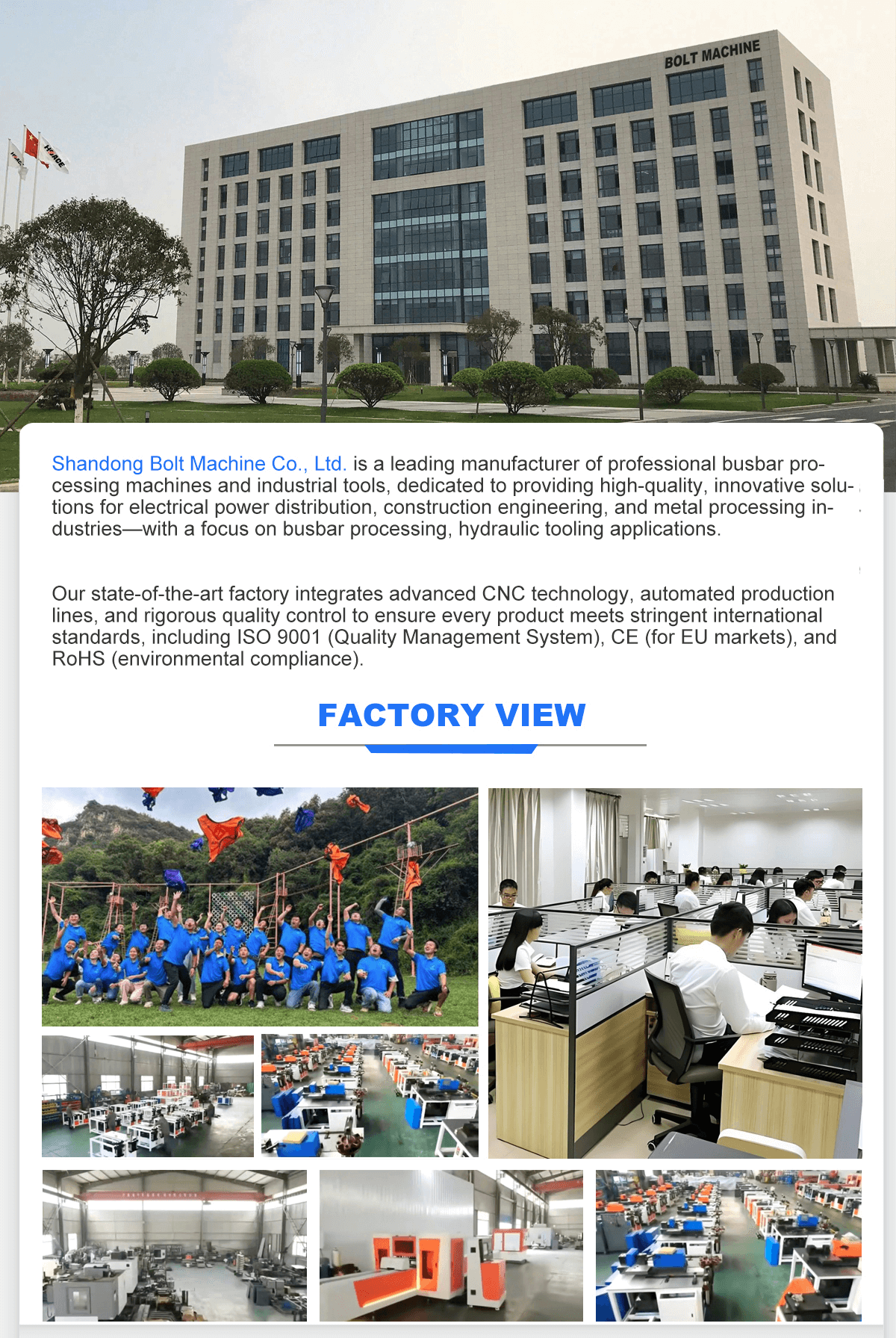

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures