- BOLT

- BT-C303S/BT-503S/BT-803S

Automatic Servo Turret CNC Three-table Busbar Processing Machine with punching, shearing, bending units. Fast-adjust modules cut processing time, boosting efficiency by 30%+. Turret die system, 50-ton hydraulic punching, and 45# steel bending dies ensure precision. Smooth shearing with zero waste. Dual controls (foot pedal + buttons) for ease. Suitable for copper/aluminum busbars, CE & ISO certified. Ideal for electrical manufacturing.

Product details

Automatic Servo Turret CNC Three-table Busbar Processing Machine integrates multi-functions, 4-servo material stops, 3-pump with 3-station configuration with automatic positioned punching, shearing and bending functions.

1. All-in-One Work Units

-Automatic punching, shearing, and bending units with quick-adjust features reduce processing time and boost efficiency by 30%+.

- Processes copper and aluminum busbars up to 16mm thickness with precision tooling.

- Modular design allows seamless switching between operations, minimizing workflow downtime.

2. Precision Measurement System

- Each workbench features calibrated measuring scales for accuracy within ±0.2mm.

- Dual-control options (foot pedal + manual buttons) enable flexible operation and emergency stops.

3. Tooling Flexibility

- Interchangeable dies support various busbar sizes (30×5mm to 120×12mm) and custom processing needs.

- Quick-release mechanisms for fast die changes, optimizing setup time.

Punching Unit Highlights

- Turret-style Die System: 6-station automatic indexing reduces die change time to <3 seconds (5x faster than manual systems).

- High-Force Hydraulics: 80mm diameter cylinder with 50-ton punching capacity, ensuring clean holes in 16mm aluminum without burrs.

- Polyurethane Spring Ejection: Speeds up material release by 40%, preventing jams and improving workflow.

- Dual Control Modes: Foot pedal and button operation for intuitive, hands-free processing.

Bending Unit Highlights

- Horizontal Workflow: Safe, ergonomic design with clear visibility for operator safety.

- Heat-Treated Dies: 45# steel quenched to HRC52-55 for over 100,000 cycles of precision 90°-180° bending.

- Closed-Frame Structure: 60% stiffer than open frames, ensuring uniform pressure distribution and ≤0.5mm/m linearity error.

Shearing Unit Highlights

- File-Shear Cutting: Cr12MoV alloy blades produce Ra≤1.6μm smooth edges with zero burrs or deformation.

- Zero-Waste Design: Optimized blade angle eliminates material loss, ideal for high-value conductors.

- Elastic Buffer System: Polyurethane cushion extends blade life by 3x while reducing vibration.

| Item | BT-C303S | BT-503S |

|---|---|---|

| Nominal force (kN) | 300 | 500 |

| Punching dia. range (mm) | φ4.3 ~ φ26 | φ4.3 ~ φ36 |

| Max.thickness (mm) | 16 | 16 |

| Max.width (mm) | 200 | 260 |

| Number of servo axes | 4 | 4 |

| Punching Y-axis stroke (mm) | 1000 | 1200 |

| Punching X-axis stroke (mm) | 350 | 350 |

| Cutting X-axis stroke (mm) | 1200 | 1200 |

| Bending X-axis stroke (mm) | 1200 | 1200 |

| Precision of block gauge (mm) | 0.2 | 0.2 |

| Bending precision (degree) | ±1° | ±1° |

| Repeat bending precision (degree) | ±0.2° | ±0.2° |

| Power (kW) | 3 × 4 | 3 × 5.5 |

| Outside dimension (mm) | 1850 × 1650 × 1340 | 2015 × 1815 × 1420 |

| Total weight (kg) | 1500 | 1900 |

Technical Specifications

- Power: 3x4KW/5.5KW electric-hydraulic system

- Control: Dual-action foot pedal + PLC interface (CNC upgrade available)

- Accuracy: Bending precision ±1°, Repeatability ±0.2°

- Certifications: CE certified (EU standards) & ISO 9001.

Main component:

Siemens PLC

Schneider Electric AC contactor

Schneider Electric thermal overload relay

Schneider Electric circuit breaker

Customer Benefits

- Time Savings: 65% faster than standalone machines for end-to-end processing.

- Cost Efficiency: Reduces annual tooling costs by $2,000+ through rapid die changes and zero waste.

- Safety: CE-certified hydraulic system with enclosed frames reduces operator risk by 90%.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

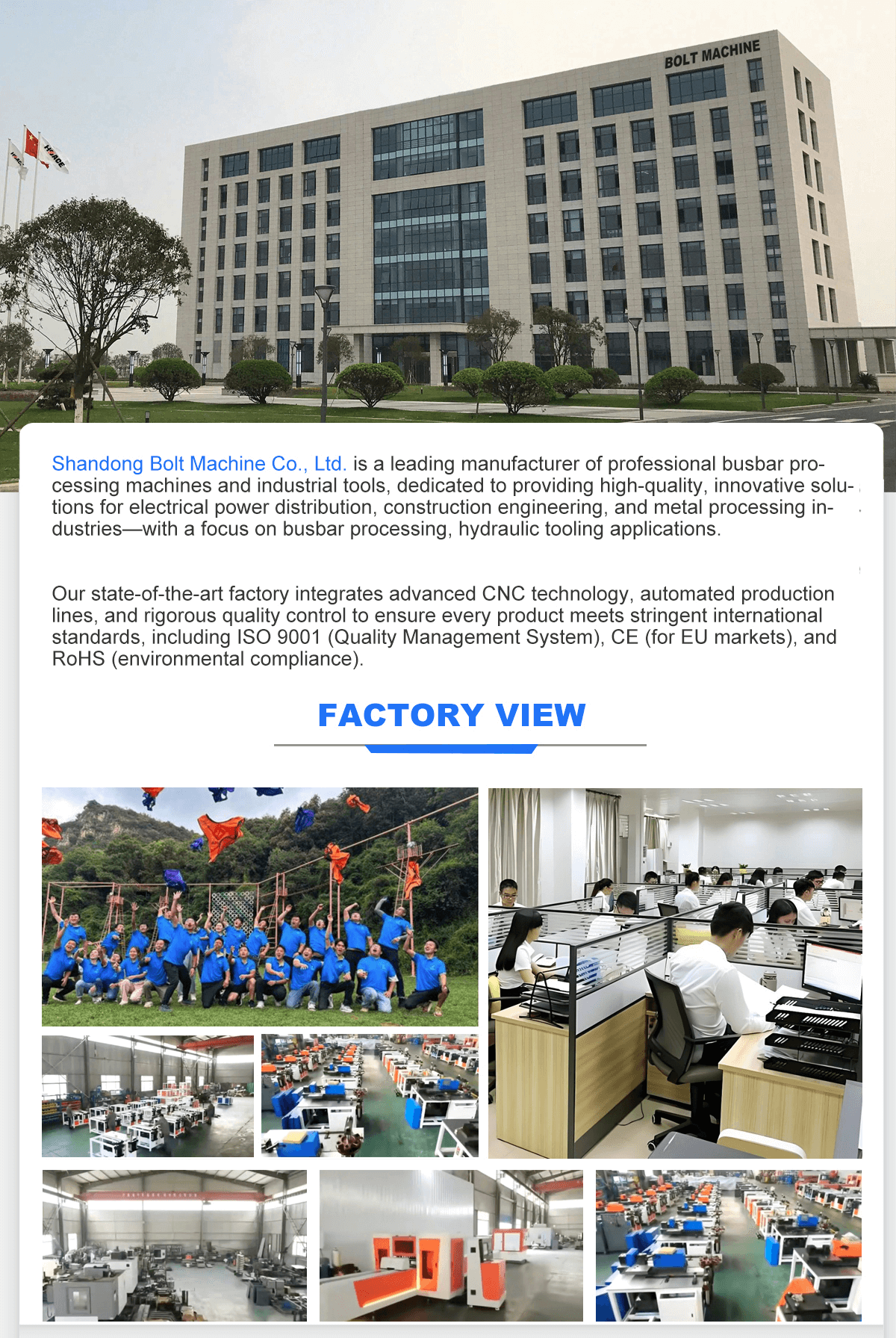

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures