- BOLT

- BT-CM200

CNC Busbar Chamfering Machine offers automatic 0-45° chamfering with ±0.05mm precision for copper/aluminum busbars. Ideal for switchgear, transformers & busway production.

Product details

Product Overview

The CNC Busbar Chamfering Machine is a high-efficiency busbar processing equipment independently developed by our company, integrating automatic positioning, automatic clamping, and automatic chamfering. Equipped with a high-precision CNC system, it is designed for fast and accurate edge chamfering of copper and aluminum busbars. With advantages such as high precision, user-friendly operation, and stable performance, it significantly improves production efficiency while reducing labor costs. It is widely used in LV/MV switchgear, transformers, busways, and new energy power distribution systems.

Key Features

1. Fully Automated Processing, High Precision

Automatic Positioning: Servo-driven system with high-precision linear scales ensures positioning accuracy of ±0.05mm for consistent results.

Automatic Clamping: Hydraulic/pneumatic clamping options (max. processing width 200mm, thickness 15mm) provide secure and stable hold.

Automatic Chamfering: High-performance spindle motor (optional 3kW/4.5kW) enables 0°~45° multi-angle chamfering with smooth, burr-free finishes.

2. Intelligent CNC System, Easy Operation

Industrial-grade CNC control system (optional Siemens/Fanuc/Taiwan Syntec) with graphical programming and multi-program storage.

Touchscreen HMI for intuitive parameter setting, allowing quick setup even for non-specialists.

3. Robust Construction, Long Service Life

One-piece cast iron body + hardened guideways for superior vibration resistance and durability.

Taiwan HIWIN linear guides + ball screws ensure smooth operation and extended lifespan.

4. Safety & Eco-Friendly Design

Fully enclosed cover prevents chip splashing; includes dust extraction port for workshop compatibility.

Low noise operation (<75dB), meeting industrial environmental standards.

Technical Specifications

| type | Horizontal | warranty | 12 Months |

|---|---|---|---|

| spindle taper | BT40 | cnc control system | Siemens |

| table travel (x) (mm) | 450 | table travel (y) (mm) | 550 |

| positioning accuracy (mm) | ±0.2 | repeatability (x/y/z) (mm) | ±0.05 |

| voltage | 380V, 220V | table travel (z) (mm) | None |

| range of spindle speed (r.p.m) | 0 - 4500 | number of axes | 2 |

| no. of spindles | 2 | machining capacity | Light Duty |

| weight (kg) | 2500 | max. table load(kg) | 200 |

| place of origin | Shandong, China | brand name | BOLT |

| model number | BT-CM200 | dimension(l*w*h) | 2500*2200*1750 |

| machinery test report | Provided | video outgoing-inspection | Provided |

| After-sales Service Provided | Online Support Video Technical Support | Condition | New |

| CNC or Not | CNC | Maximum spindle speed | 8000 Cycles/minute |

| Tool Holder model | BT40 | Tool Diameter | 100 |

| Max Processing | 160*15mm | Usage | Copper and aluminum busbar milling machine |

| Keyword | CNC Chamfering machine | Color | BLUE WHITE/RED WHITE |

Applications

✔ LV/MV switchgear busbar processing

✔ Transformer winding copper bar chamfering

✔ New energy battery packs / PV power distribution connectors

✔ Busway (bus duct), compact substations

Why Choose Our CNC Chamfering Machine?

✅ In-House R&D—Patented core technology, OEM-free, fast after-sales support.

✅ Multi-Functional—Supports V-type, C-type, and radius chamfering in one machine.

✅ Lifetime Maintenance—Free operation training, 24/7 technical support.

Custom solutions available! (Optional auto-feeding system or production line integration)

Certifications:

CE certified (EU standards) & ISO 9001.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

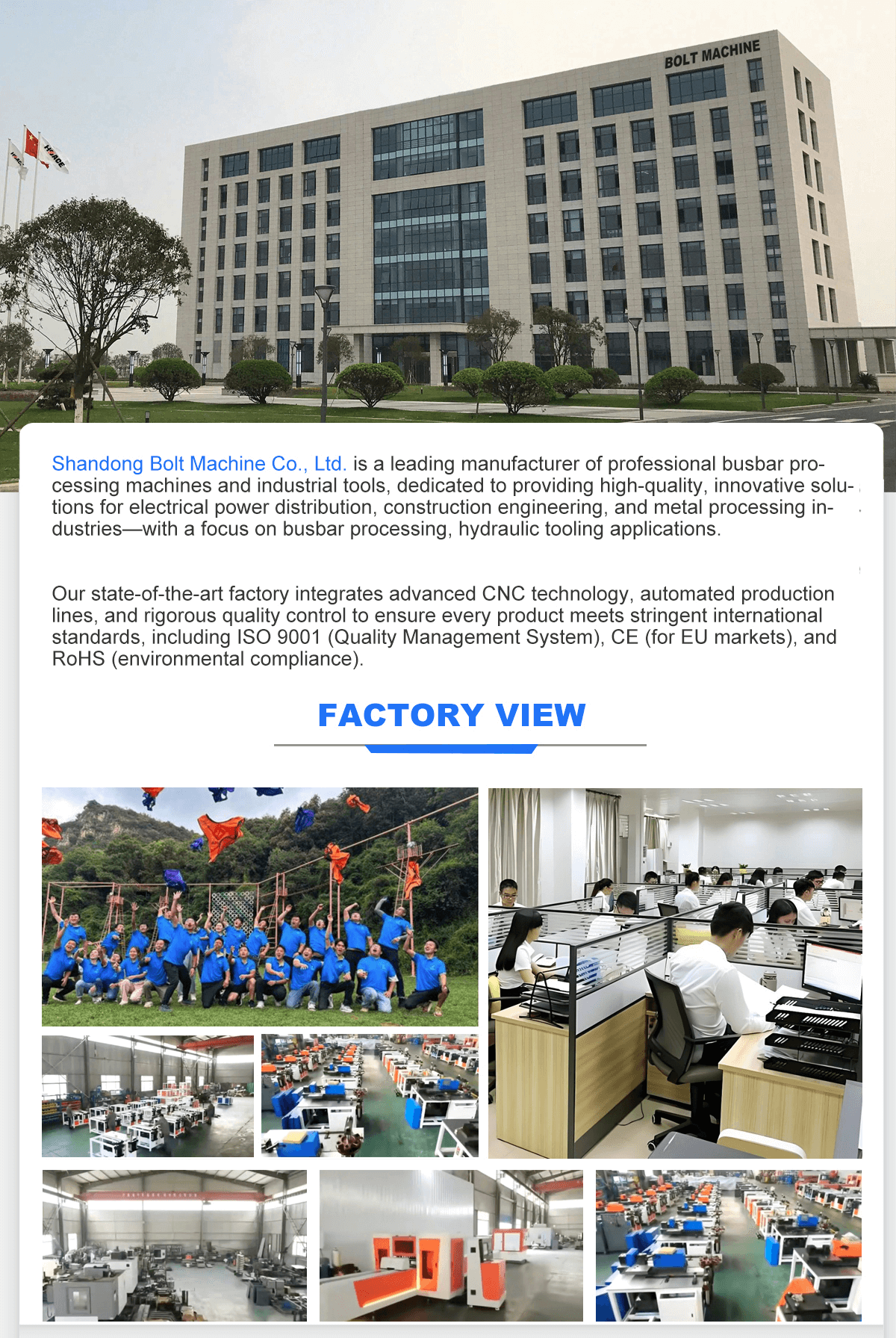

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures