- BOLT

- FW-1600-4/FW-1400-4/FW-1400-2/FW-1600-2/FW-800/FW-1200/FW-1400/FW-1600

Transformer Foil Winding Machine – Automated PLC-controlled equipment for precision coil production. Features hydraulic unwinding, two-stage tension & magnetic clutch. Reduces transformer loss 30%+. Request quote!

Product details

Our Transformer Foil Winding Machine is the specialized equipment for manufacturing transformer foil windings (also known as box-type coils). It utilizes copper or aluminum foil strips of varying thicknesses as conductors, with wide-band insulating material for inter-layer insulation and narrow-band insulating material for end insulation. The machine completes the entire winding process in a single operation, forming a wound coil while simultaneously performing lead welding on both the inner and outer sides and applying surface wrapping.

Our Transformer Foil Winding Machine is the specialized equipment for manufacturing transformer foil windings (also known as box-type coils). It utilizes copper or aluminum foil strips of varying thicknesses as conductors, with wide-band insulating material for inter-layer insulation and narrow-band insulating material for end insulation. The machine completes the entire winding process in a single operation, forming a wound coil while simultaneously performing lead welding on both the inner and outer sides and applying surface wrapping.

Key Features & Advantages:

PLC Automation & Control: Equipped with PLC automatic control and a variable-frequency stepless speed regulation system, ensuring precise operation and industry-leading performance.

Reduced Transformer Losses: Engineered to significantly reduce transformer losses.

Hydraulic Material Unwinding: Features a hydraulic expansion/contraction mechanism on the unwinding head for easy and labor-saving operation.

Precision Foil Tension Control: Employs a two-stage tension control system. Maintains accurate, consistent tension during forward winding, stopping, and unwinding, guaranteeing solid and compact coils.

Advanced Insulation Handling: Layer insulation paper tension is managed using an air shaft and magnetic powder clutch, enabling quick material changes and effortless tension adjustment.

Main Technical Parameters

| No. | Item | BOLT-BRJ-1400 | BOLT-BRJ-1100 | BOLT-BRJ-800 |

|---|---|---|---|---|

| 1 | Coil Processing Range | |||

| Axial Length | 500-1400MM | 250-1100 | 180-800 | |

| Axial Length (with leads) | 650-1550 | 400-1250 | 330-950 | |

| Outer Diameter (excluding arrangement) | Φ700 | Φ700 | Φ700 | |

| Max Outer Diameter | Φ800 | Φ800 | Φ800 | |

| Min Inner Diameter | Φ130 | Φ100 | Φ100 | |

| 1.6 | Coil Shape | Circular/Rectangular | Circular/Rectangular | Circular/Rectangular |

| 2 | Coil Material | |||

| Material | Steel Structure | Steel Structure | Steel Structure | |

| Width | 450-1250MM | 200-1050MM | 180-750MM | |

| 2.3 | Thickness | Steel: 0.5-2MM Aluminum: 0.5-3MM | 0.3-2 0.5-3 | 0.3-2 0.5-3 |

| 3 | Uncoiler | |||

| Coil Inner Diameter | Φ400K50 | Φ400K50 | Φ400K50 | |

| Coil Outer Diameter | Φ1000 | Φ1000 | Φ1000 | |

| Effective Length of Material Holder | 1400MM | 1150MM | 850MM | |

| Expansion Range of Material Holder | Φ400-520 | Φ400-520 | Φ400-520 | |

| Material Holder Capacity | 2000KG | 2000KG | 1000KG | |

| Expansion Force | 1.0-18000N 2.0-30000N | 1.0-12000N 2.0-20000 | 1.0-10000N | |

| Expansion Working Pressure | 0-0.6(MPa) | 0-0.6(MPa) | 0-0.6(MPa) | |

| 4 | Winding Machine | |||

| Working Torque | >12000-NM | >10000-NM | >8000NM | |

| Winding Power | Double Layer: 18.5KW Single Layer: 18.5KW | Double Layer: 18.5KW Single Layer: 15KW | Double Layer: 15KW Single Layer: 11KW | |

| Speed Control Method | Frequency Conversion Stepless Speed Regulation | Frequency Conversion Stepless Speed Regulation | Frequency Conversion Stepless Speed Regulation | |

| Winding Shaft | 50x90x1850MM | 50x90x1550MM | 50x90x1250MM | |

| 4.5 | Winding Speed | 0-20(r/min) | 0-25(r/min) | 0-30(r/min) |

| 5 | Welding Method | TIG | TIG | TIG |

| Welding Speed | Automatic 0-1M/MIN | Automatic 0-1M/MIN | Automatic 0-1M/MIN | |

| 6 | Cutting Method | Lead Screw Circular Blade | Lead Screw Circular Blade | Lead Screw Circular Blade |

| Cutting Strength | 1.5M/MIN | 1.5M/MIN | 1.5M/MIN | |

| Cutting Length | 1400MM | 1100MM | 800MM | |

| 7 | Insulation Mounting Shaft | 1 set | 1 set | 1 set |

| Shaft Outer Diameter | Φ400MM | Φ400MM | Φ400MM | |

| Inner Diameter | 76MM | 76MM | 76MM | |

| Available Shaft Length | 1400 | 1100 | 800 | |

| 8 | End Edge Screws | |||

| Quantity | 10 sets (customizable) | 10 sets (customizable) | 4 sets (customizable) | |

| Outer Diameter | Φ350MM | Φ350MM | Φ350MM | |

| Inner Diameter | 56MM | 56MM | 56MM | |

| Width | 15-50MM | 15-50MM | 15-50MM | |

| 9 | Electrical Control System | PLC Automatic Control | PLC Automatic Control | PLC Automatic Control |

| 10 | Counting Accuracy | 0.1 turn | 0.1 turn | 0.1 turn |

| 11 | Alignment Correction Method | Servo System | Servo System | Servo System |

| 11.1 | Alignment Correction Accuracy | ±0.1(mm) | ±0.1(mm) | ±0.05(mm) |

| 11.2 | Single Layer Machine Dimensions | 4600mm×2850mm×2200mm | 4300mm×2600mm×2000mm | 3800mm×2300mm×1800mm |

| 11.3 | Double Layer Machine Dimensions | 6200mm×2850mm×2500mm | 5500mm×2600mm×2250mm | 4800mm×2300mm×2050mm |

| No. | Item | BOLT-BRJ400-2 | BOLT-BRJ600-2 | BOLT-BRJ800-2 | BOLT-BRJ1000-2 | BOLT-BRJ1400-2 |

|---|---|---|---|---|---|---|

| 1 | Coil Processing Range | |||||

| Axial Length | 400mm | 600mm | 800mm | 1000mm | 1400mm | |

| Axial Length (with leads) | 550mm | 750mm | 950mm | 1150mm | 1550mm | |

| Max Outer Diameter | Φ600 | Φ800 | Φ800 | Φ1000 | Φ1000 | |

| Min Inner Diameter | Φ130 | Φ130 | Φ130 | Φ130 | Φ130 | |

| 1.5 | Coil Type | Circular/Rectangular | ||||

| 2 | Coil Material | |||||

| Material | Copper foil/Aluminum foil | |||||

| Width | 400mm | 600mm | 800mm | 1000mm | 1400mm | |

| Thickness | Copper foil: 0.2-2.0mm Aluminum foil: 0.3-3.0mm | |||||

| Coil Inner Diameter | Φ400/Φ500 | Φ400/Φ500 | Φ400/Φ500 | Φ400/Φ500 | Φ400/Φ500 | |

| 2.5 | Coil Outer Diameter | Φ1000 | Φ1000 | Φ1000 | Φ1000 | Φ1000 |

| 3 | Uncoiler | |||||

| Effective Length of Material Holder | 450mm | 650mm | 850mm | 1050mm | 1450mm | |

| Expansion Range of Material Holder | Φ400-Φ520 | Φ400-Φ520 | Φ400-Φ520 | Φ400-Φ520 | Φ400-Φ520 | |

| Material Holder Capacity | 500KG | 1000KG | 1500KG | 2000KG | 2500KG | |

| Expansion Force | 0-6000N.M | 0-10000N.M | 0-14000N.M | 0-18000N.M | 0-30000N.M | |

| 3.5 | Expansion Working Pressure | 0-0.6(MPa) | 0-0.6(MPa) | 0-0.6(MPa) | 0-0.6(MPa) | 0-0.6(MPa) |

| 4 | Winding Machine | |||||

| Working Torque | ≥3000N.M | ≥4000N.M | ≥5000N.M | ≥6000N.M | ≥10000N.M | |

| Winding Power | 7.5KW | 7.5KW | 7.5KW | 11KW | 11KW | |

| Speed Control Method | Frequency Conversion Stepless Speed Regulation | |||||

| Winding Shaft | 80×80×750mm | 80×80×950mm | 80×80×1150mm | 80×80×1350mm | 80×80×1750mm | |

| 4.5 | Winding Speed | 0-30r/min | 0-26r/min | 0-24r/min | 0-20r/min | 0-18r/min |

| 5 | Welding Device | |||||

| Welding Method | TIG | TIG | TIG | TIG | TIG | |

| 5.2 | Welding Speed | 0-0.8m/min | 0-0.8m/min | 0-0.8m/min | 0-0.8m/min | 0-0.8m/min |

| 6 | Cutting Device | |||||

| Cutting Type | Electric Rotary Shear | |||||

| Cutting Speed | 0.8m/min | 0.8m/min | 0.8m/min | 0.8m/min | 0.8m/min | |

| 6.3 | Cutting Length | 400mm | 600mm | 800mm | 1000mm | 1400mm |

| 7 | Deburring Device | Pneumatic Adjustable | ||||

| 8 | Cleaning Device | Pneumatic Adjustable | ||||

| 9 | Layer Insulation Uncoiler | |||||

| Layer Insulation Mounting Shaft | 2 sets | 2 sets | 2 sets | 2 sets | ||

| Layer Insulation Outer Diameter | ≤Φ400mm | ≤Φ400mm | ≤Φ400mm | ≤Φ400mm | ||

| Layer Insulation Inner Diameter | Φ76mm | Φ76mm | Φ76mm | Φ76mm | ||

| Layer Insulation Width | ≤450mm | ≤650mm | ≤850mm | ≤1050mm | ≤1450mm | |

| Expansion Method | Pneumatic Expansion | |||||

| 9.6 | Uncoiling Tension | Pneumatic, Stepless Adjustable | ||||

| 10 | End Insulation Device | |||||

| Quantity | 8 sets | 8 sets | 8 sets | 8 sets | ||

| 11 | Alignment Correction Device | |||||

| Alignment Correction Method | Ball Screw Automatic Alignment | |||||

| 11.2 | Alignment Correction Accuracy | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) | ±0.5(mm) | |

| Control Method | PLC Automatic Control | |||||

| Counting Digits | 4 digits (0-9999.9) | |||||

| 12.3 | Counting Accuracy | 0.1 turn | ||||

(Only list some model parameters)

Customization is also available to meet specific customer requirements.

Certifications:

CE certified (EU standards) & ISO 9001.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

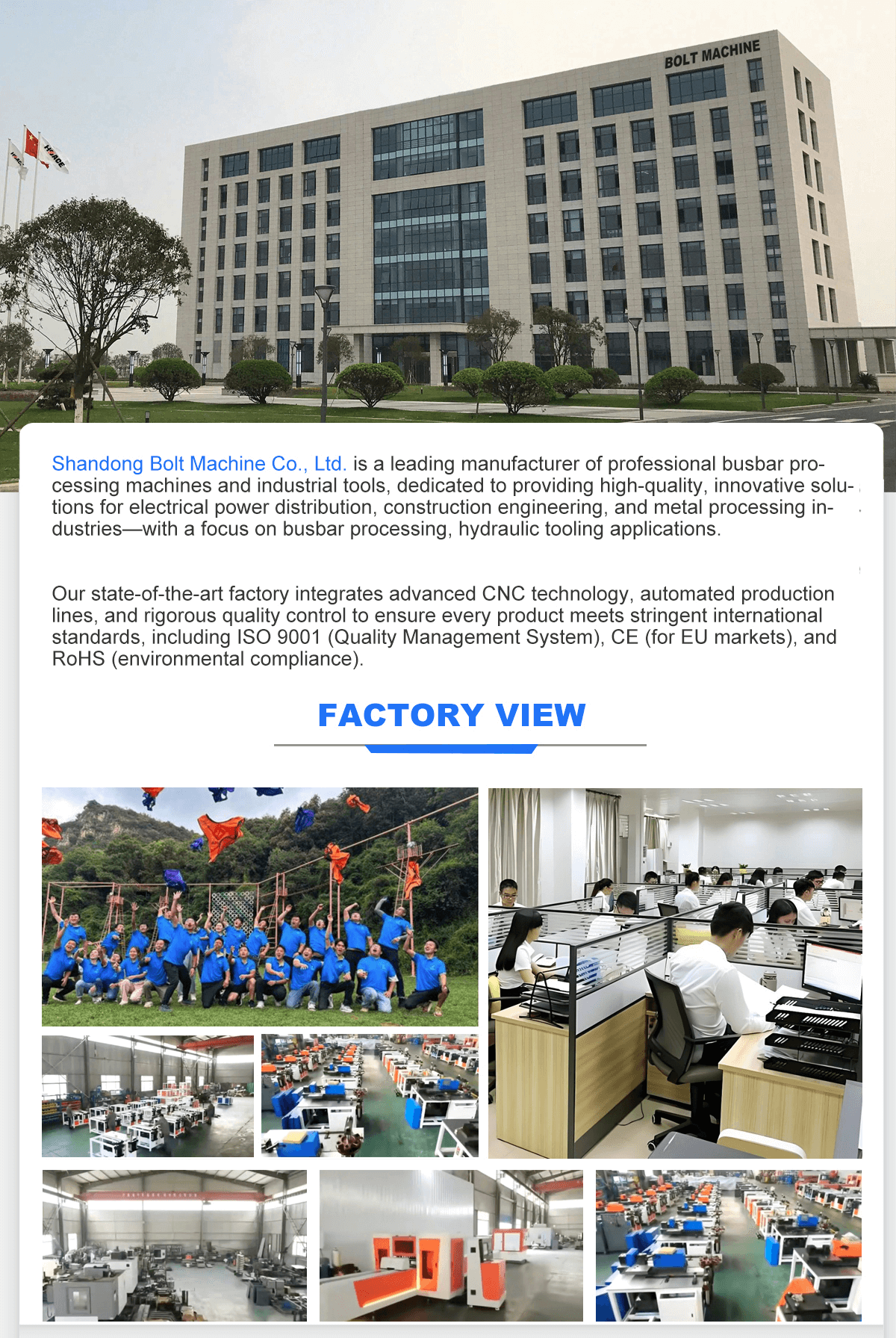

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures