- BOLT

- CW-1/CW-2/CW-3/CW-03/CW-05

horizontal transformer coil winding machine, a key asset in power equipment manufacturing. Certified with ISO9001-2008, CE, Patent, and China Export Quality certifications, it features a user-friendly digital display for precise, efficient winding. Ideal for power transformers and motor coils, it serves global leaders like Toshiba Japan and Luneng Electric. Available in multiple specifications with customizable options and multilingual manuals. Boost your production with reliable, high-quality coil winding technology.

Product details

Product Introduction

The BOLT-CW type horizontal transformer coil winding machine, as a specialized equipment focused on winding transformer coils, has become a powerful assistant in the field of power equipment manufacturing by virtue of its excellent performance and stable quality.

This equipment has obtained a number of authoritative certifications, including ISO9001-2008 Quality Management System Certification, CE Certification, Patent Certification, and Export Quality Certification issued by the China Inspection and Quarantine Bureau, fully demonstrating its strong strength in quality control and compliance.

In terms of technology, it integrates cutting-edge international technologies and is specially designed for the special needs of transformer coil winding. Equipped with a user-friendly digital display, it makes operation more convenient and intuitive. Operators can easily control the winding parameters and processes, greatly improving production efficiency and precision.

It has a wide range of applications and plays an important role in industries such as power transformers and motor coils. With its reliable performance and accurate winding effect, it has won consistent recognition from customers in the global market. At present, it has provided stable services for leading enterprises in the industry such as Toshiba Japan and Luneng Electric, and has become a key equipment in the production lines of many well-known enterprises, helping them achieve efficient and high-quality coil manufacturing.

Technical Parameters

| Item | Horizontal Transformer Coil Winding Machine | ||||

|---|---|---|---|---|---|

| Product model | CW-1(0.5T) | CW-2(1T) | CW-3(2T) | CW-03 | CW-05 |

| Center height | 1000mm | 1000mm | 1000mm | 1200mm | 1200mm |

| Disk diameter | 200mm | 260mm | 300mm | 300mm | 400mm |

| Spindle speed | 0-180 r/min | 0-100 r/min | 0-80 r/min | 0-50 r/min | 0-30 r/min |

| Line mold length | 1000mm | 1200mm | 1250mm | 1300mm | 1300mm |

| Max capacity | 500kg | 1000kg | 2000kg | 3000kg | 5000kg |

| Motor power | 3kw | 4kw | 5.5kw | 5.5kw | 7.5kw |

| Power Supply | Customized according to requirements | ||||

| Speed regulation method | Variable Frequency Speed Regulation | ||||

| Restart at | Six-digit Display Counter (Auto-direction Sensing for Forward/Reverse Counting) | ||||

| Equipment weight | 350kg | 500kg | 800kg | 1200kg | 1500kg |

Since its commissioning, it has been widely used in specialized products such as E1 transformers, three-phase transformers, reactors, power transformers, control transformers, and dry-type power transformers.

Randomly included are product operation manuals in multiple languages and operation video tutorials.

Certifications:

CE certified (EU standards) & ISO 9001.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

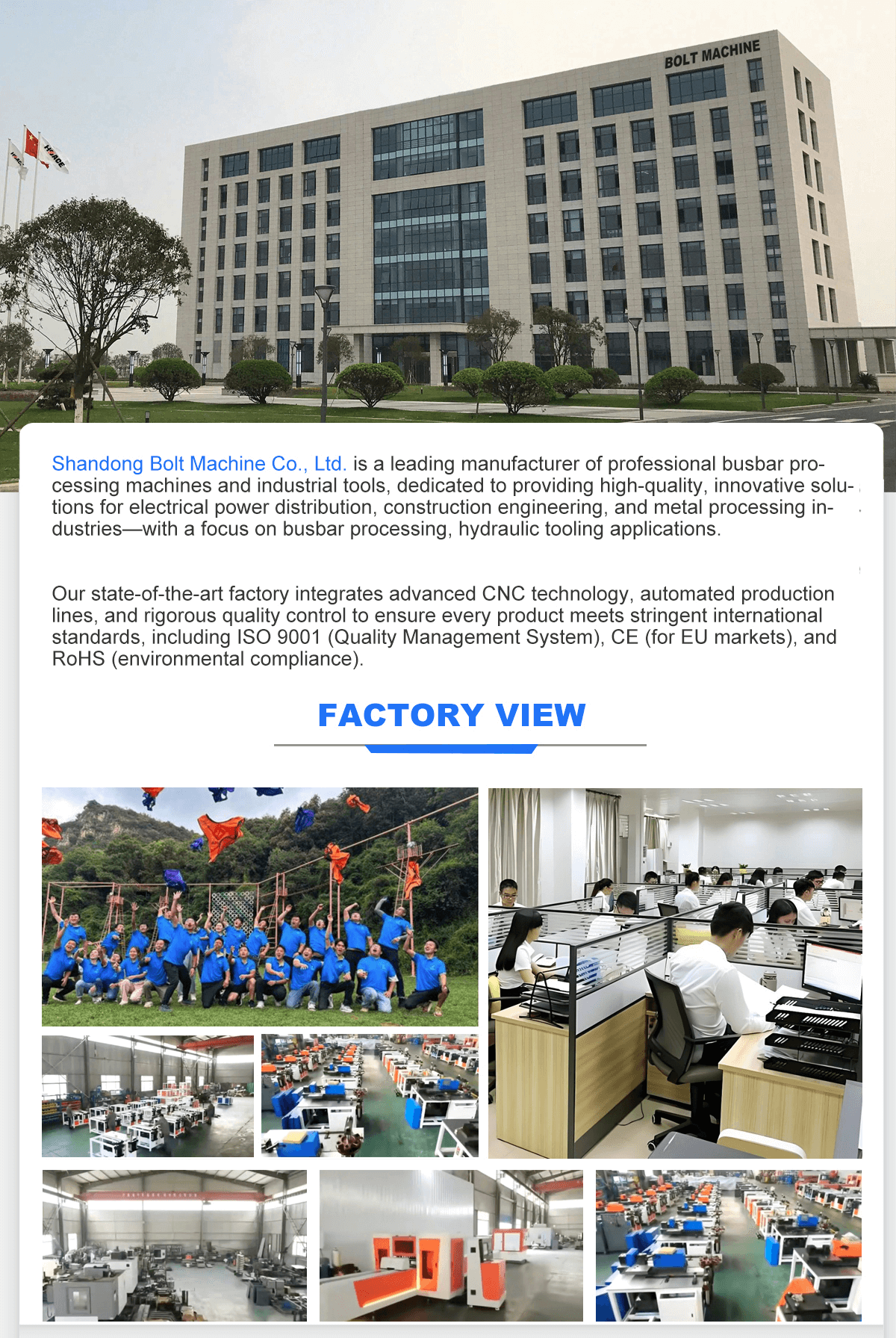

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures