- BOLT

- BT-CB1216

1. Description of Automatic Copper Tube Straightening, End Forming, and Bending MachineThis machine is specially designed for decoiling, straightening, end forming, bending, and cutting coil copper tubes into various shapes, widely used in air conditioners and heat exchangers.It integrates straighte

Product details

1. Description of Automatic Copper Tube Straightening, End Forming, and Bending Cutting Machine

This machine is specially designed for decoiling, straightening, end forming, bending, and cutting coil copper tubes into various shapes, widely used in air conditioners and heat exchangers.

It integrates straightening, cutting, flaring, and bending into a single unit. A robotic manipulator automatically transfers the flared tubes to the bending station, ensuring smooth and precise operations.

The system is PLC-controlled with HMI operation, offering fully automatic performance, high consistency, and no manual labor requirements. It delivers high efficiency, with each bend completed in just 3–4 seconds.

2. Main Configuration of Copper Tube Straightening, End Forming, and Bending Machine

PLC & HMI: Mitsubishi (Japan)

Bending Controller: FUNS

Servo Motor & Driver: Mitsubishi (Japan)

Circuit Breaker: FUJI (Taiwan)

Buttons & Relay: IDEC (Japan)

Pneumatic Components: AIRTAC (Taiwan)

Hydraulic Components: Renowned Taiwan brands

Linear Guide: LSK (Japan)

Ball Screw: TBI (Taiwan)

| No. | Item | Data | ||

| 1 | Suitable copper/aluminum tube material | Hard / soft | ||

| 2 | Suitable copper tube reel size | Max. weight 280kg; Max. OD: Ф1250mm; ID: Ф130mm | ||

| 3 | Suitable copper tube diameter | Max. Φ16mm x 1.2mm | ||

| 4 | Bending station | Bending radius | Max. R 60mm; Min. R 10mm | |

| 5 | Max. Workpiece length | 1200mm | ||

| 6 | Feeding axis (X) | Stroke | 0 - 1200mm | |

| 7 | Speed | 0 - 1200mm/sec | ||

| 8 | Precision | ±0.05mm | ||

| 9 | Rotating axis (Y) | Angle | 0 - ±360° | |

| 10 | Speed | 0 - 600°/sec | ||

| 11 | Precision | ±0.05° | ||

| 12 | Bending axis (Z) | Angle | 0 - 200° | |

| 13 | Speed | 0 - 300°/sec | ||

| 14 | Precision | ±0.05° | ||

| 15 | Decoiling & straightening station | One-time feeding stroke | Max. 1000mm | |

| 16 | Linear straightness error | ≤2‰ | ||

| 17 | Re-positioning error | When L≤1000mm, ≤0.3mm When L≥1000 mm, ≤0.6mm | ||

| 18 | Tube end ID reduction ratio | f < 20% * | ||

| 19 | Length difference between tubes | ≤0.5mm (L=1000) | ||

| 20 | Surface condition after cut | No apparent scratch, drawing marks; no burrs | ||

| 21 | Roundness of cut tubes | When diameter ≤ ф12.7, ≤3% When diameter >ф12.7, ≤0.4mm | ||

| 22 | End forming station | Power | Hydraulic | |

| 23 | Working-station | 1 | ||

| 24 | End forming method | Cold forging / spinning | ||

| 25 | Overall equipment effectiveness | 3~4 seconds per bend | ||

| 26 | Electric power | 380V / 50Hz / 4kW Customizable voltage | ||

| 27 | Whole line dimension | L4000 x W1000 x H1300mm | ||

| 28 | Whole weight | 900kg | ||

| 29 | Pneumatic source | 0.5 - 0.7MPa | ||

| 30 | Hydraulic pressure | 5 - 7MPa | ||

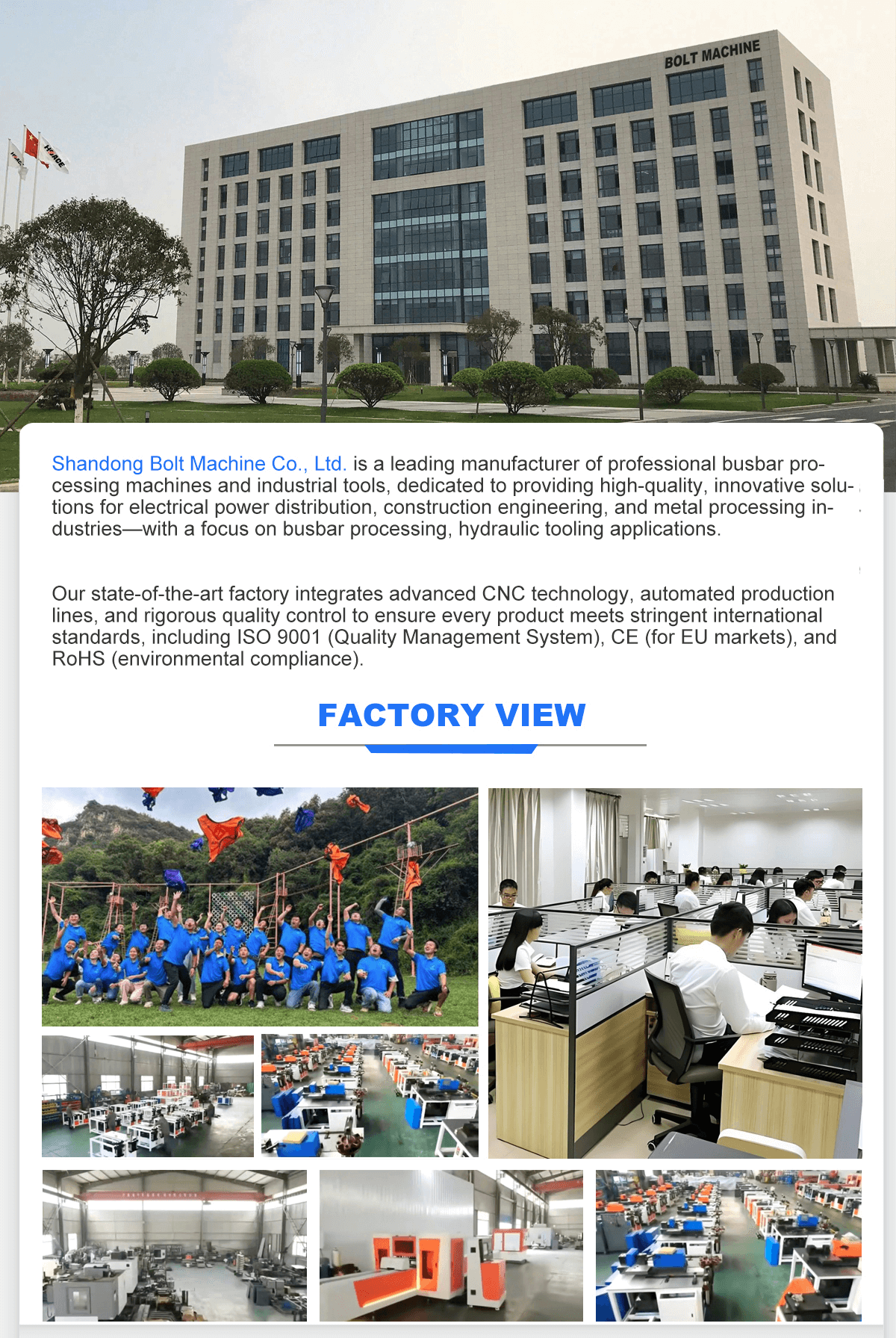

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures