- BOLT

- BT-CP703/BT-CP901

BT-CJ703/BT-CJ902 CNC Busbar punching shearing Machine integrates automatic feeding, punching, cutting & embossing, ideal for copper/aluminum busbar processing in power industries (switchgear, transformers, etc.). Equipped with Siemens servo control (X/Y/Z axes), it ensures ±0.1mm positioning and ±0.2mm punching precision. Double-clamp design stabilizes workpieces; automatic typesetting and direct CAD/SolidWorks program generation boost efficiency.

Product details

Product Introduction

CNC Busbar Punching Shearing Machine is a kind of machine with functions including automatic feeding, automatic positioning, automatic clamping, automatic punching, automatic cutting, automatic embossing, automatic mold replacement and automatic delivery. As a professional processing equipment for copper and aluminum busbars, it features accurate positioning and high reliability. It is widely used in high and low voltage complete sets, switchgear, transformer manufacturing, box-type substations, busways and other electric power industries.

Technical Parameters

| Item | BT-CP703 | BT-CP902 | |

| Nominal Force | 600kn | 600kn | |

| Max. Processing Width | 200mm | 200mm | |

| Max. Processing Thickness | 16mm | 16mm | |

| Die Number | Punching | 7 | 9 |

| Cutting | 1 | 1 | |

| Embossing | 1 | N/A | |

| Punching Precision | ±0.20mm | ±0.20mm | |

| Embossing Area | 200*50mm2 | N/A | |

| Punching Range | Φ4.3-35mm | Φ4.3-35mm | |

| Control Axes Number | six | six | |

| Punching Frequency | 10-180time/min (stroke 20mm) | 10-180time/min (stroke 20mm) | |

| Main/Vice Clamp Axis Max. Stroke | 185mm | 205mm | |

| Cylinder Stroke | ≥45mm | ≥45mm | |

| Outside Dimension | 10500*2700*1850 | 10500*2700*1850 | |

| Motor Power | 20KW | 20KW | |

| Machine Weight | 6000kg | 6000kg | |

Product Features

CNC Busbar punching shearing Machine consists of a feeding table, a mold/die group, a conveying table, a hydraulic power system, and a servo control system.

The X, Y, and Z axes are all controlled by the German Siemens servo system. Operators can directly create CAD 2D drawings or SolidWorks 3D models on the equipment’s computer to generate processing programs directly, or save them for cyclic processing. Additionally, drawn CAD 2D drawings or SolidWorks 3D models can be directly imported into the equipment to generate processing programs, or the drawing-generated programs can be directly called via the local area network. The system is equipped with an automatic typesetting function, making it more efficient and cost-effective.

It adopts a double-clamp working method, which improves the stability of workpieces during punching and cutting, as well as processing efficiency and accuracy.

The mold/die group includes either seven punching dies, one shearing die, and one embossing die, or nine punching dies and one shearing die.

The shearing station adopts a punch-shearing mode, ensuring no sagging or burrs.

The punching die uses separate punching and piercing dies, which are lower in cost and easy to replace.

Main component:

Siemens PLC

Schneider Electric AC contactor

Schneider Electric thermal overload relay

Schneider Electric circuit breaker

Certifications:

CE certified (EU standards) & ISO 9001.

Packaging & Lead time

Wrapped with waterproof plastic film inside and wooden cases outside.

Within 3-15 days after payment.

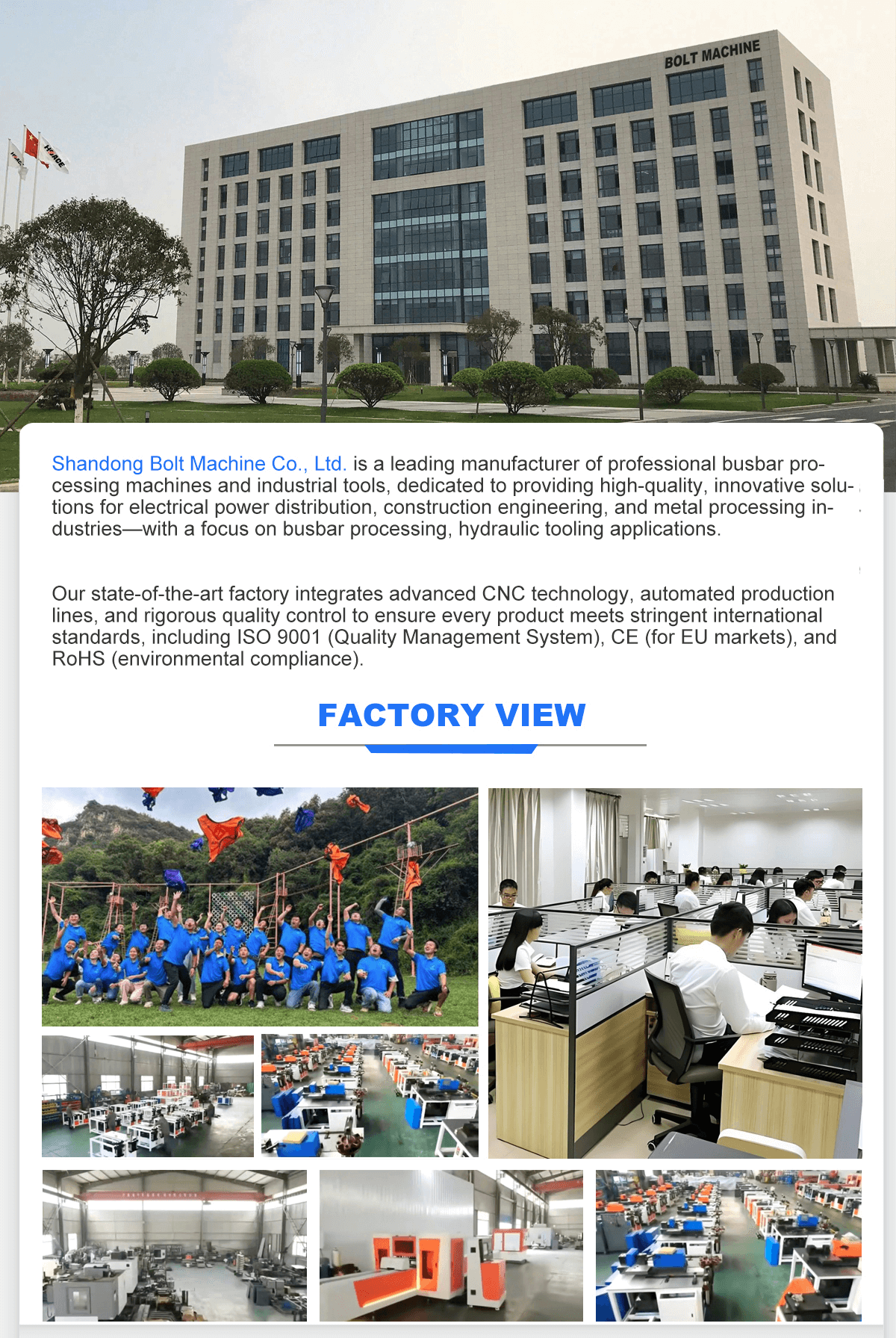

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures