- BOLT

- SSKG-3015

Discover the power of fiber laser cutting machines, advanced tools for high-precision metal cutting, engraving, and marking. With efficient fiber laser sources (500W-30kW), CNC control, and versatile applications, these machines excel in industries like automotive, aerospace, electronics, and jewelry. Offering high speed, energy efficiency, low maintenance, and superior cut quality, they handle steel, aluminum, copper, and more. Achieve smooth edges and intricate designs with a long-lasting, reliable system.

Product details

1. What is a Fiber Laser Cutting Machine?

A fiber laser cutting machine is a high-precision industrial tool that uses a fiber laser source to cut, engrave, or mark materials. The laser beam is generated by amplifying light through optical fibers doped with rare-earth elements (like ytterbium), making it highly efficient for metal cutting.

2. Key Components

Fiber Laser Source: Generates the laser beam (typically 500W to 30kW power).

Cutting Head: Focuses the laser beam onto the material.

CNC Control System: Guides the cutting path with high precision.

Cooling System: Prevents overheating (chiller unit).

Work Bed: Supports the material (flatbed or rotary for tubes).

Exhaust System: Removes fumes and debris.

3. How It Works

The fiber laser emits a high-intensity beam.

The beam is directed through a fiber-optic cable to the cutting head.

A lens focuses the beam onto the material, melting or vaporizing it.

Assist gas (O₂, N₂, or air) blows away molten material for a clean cut.

4.Technical parameters

| Model | SSKG-3015 |

|---|---|

| Cutting Area | 3000mm*1500mm |

| Power Requirements | 380V/50Hz/3P |

| Graphic Format Supported | AI, PLT, DXF, BMP, Dst, Dwg, LAS, DXP |

| Power | 1500W |

| Cooling Mode | Water Cooling |

| Transmission Mode | Rack and pinion transmission |

| X, Y, Z axis max speed | 80m/min |

| Max Moving Speed | 100m/min, Acc=1.0G |

| Continuous Working Time | 24Hours |

| Max Linkage Speed | 60m/min |

| Positional Accuracy | ±0.03mm |

| Re-positional Accuracy | ±0.02mm |

| Packing Sizes | 2280*4500*1800MM |

| Weight | 1600KG |

5. Advantages of Fiber Laser Cutting

✔ High Speed & Precision: Faster than CO₂ lasers, especially for thin metals.

✔ Energy Efficiency: Consumes less power than CO₂ lasers.

✔ Low Maintenance: No mirrors or gas lasers to replace (unlike CO₂).

✔ Superior Cut Quality: Smooth edges, minimal burring.

✔ Versatility: Cuts steel, stainless steel, aluminum, copper, brass, and more.

✔ Long Lifespan: Fiber lasers last 100,000+ hours.

6. Applications

Automotive: Precision parts, exhaust systems.

Aerospace: Sheet metal components.

Electronics: Enclosures, heat sinks.

Jewelry: Intricate designs.

Construction: Structural steel, panels.

Medical Devices: Surgical tools.

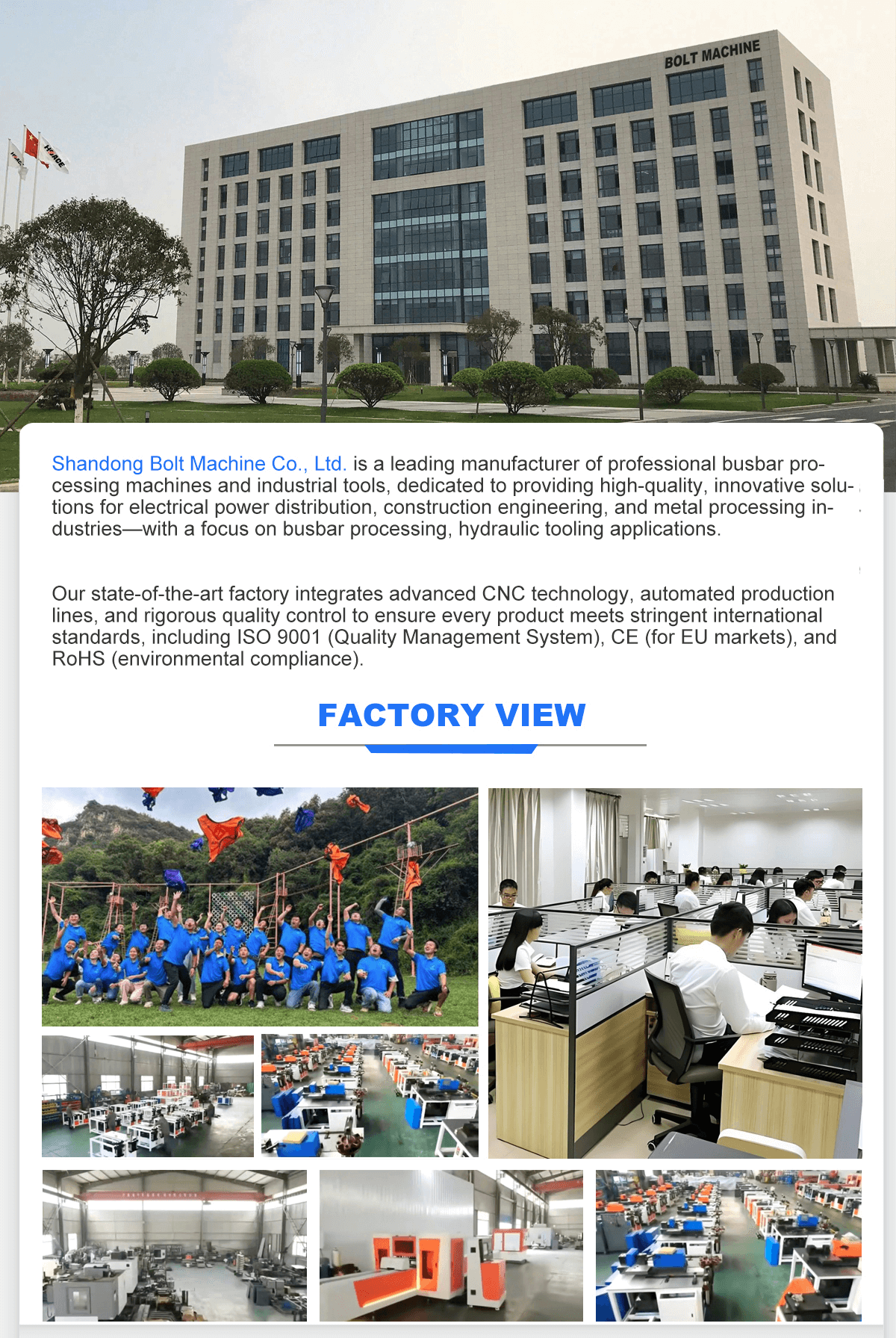

About Bolt Machine

FAQ

Q1: Are you the manufacturer?

A: Yes, we are a professional manufacturer operating more than three workshops. You are welcome to visit our factory in Jinan.

Q2: Can I purchase just one machine?

A: Absolutely! Many of our machines are plug-and-play and are ideal for small businesses. Please inform us of your budget and intended application, and we will recommend a suitable model.

Q3: Do you ship to my country? What is the freight cost?

A: Yes, we ship worldwide. Please provide your city and country, and we will propose the optimal shipping method (sea freight, air freight, or door-to-door delivery) along with an accurate freight quote.

Q4: Are import duties applicable? How about customs clearance?

A: Import duties depend on your country's regulations. Typically, you will be responsible for paying local duties/taxes. However, we will prepare all necessary documentation and can provide support if you require assistance with customs clearance.

Q5: Can I see a video of the actual machine before purchasing?

A: Certainly! We offer demonstration videos, genuine customer testimonials, and can arrange live video calls to showcase the machine in operation.

Q6: What is your production and delivery lead time?

A: Standard models typically ship within 3-15 working days. Customized equipment may require longer. We will confirm the exact timeframe upon order confirmation.

Q7: What is your warranty policy?

A: Our warranty policy is as follows:

1. Basic Warranty:

* 18 months warranty on the entire machine.

* 24 months quality guarantee on core components (excluding wear parts/consumables).

* Post-Warranty Support: Wear parts/consumables provided at agent pricing

2. Technical Support: 24/7 support via email or phone.

3. Operation Guidance:

* English manuals and video tutorials provided.

* One-on-one online training available.

* Option to dispatch professional engineers for on-site installation, commissioning, and operator training (Engineers are available for overseas deployment).

4. In Case of Malfunction:

Fault Handling:

* Remote Support: Troubleshooting guidance & repair video tutorials

* Team Training: Empower your technicians with repair procedures